AR Upper Vise Block The Definitive Gunsmithing Guide

So, what exactly is an AR upper vise block? It’s a purpose-built tool made to securely cradle an AR-15, AR-10, or similar upper receiver inside a bench vise. Its whole job is to stop you from crushing, twisting, or otherwise wrecking your receiver when you're wrenching on it. Think of it as cheap insurance for a very expensive part.

Why Your AR Build Needs a Vise Block

If you've ever tried torquing down a barrel nut and watched your upper receiver start to bow under the strain, you know that heart-in-your-throat feeling. That exact moment is why a good upper vise block is the unsung hero of any gunsmith's bench. It’s not just a handy gadget—it’s an absolute must-have if you’re serious about building or maintaining your rifle correctly.

Picture your upper receiver as a hollow aluminum can. Squeezing it directly in a heavy steel vise is a surefire way to ruin your day and your build. The vise block is designed to be a perfect internal and external support system, spreading that intense clamping pressure evenly so nothing gets damaged.

The Foundation of a Safe and Accurate Build

When you’re applying the 30 to 80 ft-lbs of torque needed to properly install a barrel nut, all that force needs a safe path. Without a solid vise block, that stress will find the weakest spot in your receiver, which can lead to a catastrophic failure.

Here’s what a vise block really does for you:

- Prevents Receiver Damage: First and foremost, it protects the relatively thin aluminum walls from being warped, cracked, or crushed by the vise.

- Ensures Proper Torque: A rock-solid platform means you can get an accurate reading on your torque wrench. That’s not just for performance—it’s a major safety factor.

- Protects the Index Pin: It takes the twisting force off the receiver, which is what saves the barrel’s small, fragile index pin from getting sheared right off.

- Maintains Perfect Alignment: Keeping everything straight and steady is critical when you’re installing barrels or lining up a gas tube. This same principle of precise fit applies when you learn more about how components like Picatinny rails for scopes are integrated.

In short, the AR upper vise block turns a high-risk job into a controlled, repeatable step. It’s the difference between a professional-grade rifle and a disaster waiting to happen.

How Different Vise Block Designs Protect Your Receiver

Not all AR upper vise blocks are built the same, and knowing the difference is crucial for protecting your firearm. You can really boil them down to two main types: external "clamshell" blocks and internal support tools, often called reaction rods. Each has a totally different philosophy on how to hold an upper receiver steady while you're wrenching on it.

A clamshell block is exactly what it sounds like—it wraps around the outside of your receiver like a protective shell. This design is all about spreading out the immense clamping pressure from your bench vise, making it a solid, reliable choice for general assembly and maintenance.

Reaction rods, on the other hand, work from the inside out. Instead of grabbing the aluminum receiver, these tools slide into the upper and lock directly into the steel barrel extension lugs. This is a game-changer because it isolates the receiver from all the twisting force (torque) you apply when tightening a barrel nut.

External Clamshell Support

The whole point of a clamshell is to distribute pressure. When you crank down a vise, all that force gets focused on two small points. A good clamshell, usually made from a tough polymer, acts as a buffer, spreading that force across a much bigger surface area so you don't crush or warp your receiver.

It’s a simple, effective design that has been a go-to on gunsmithing benches for years. It's perfect for holding an upper steady while you're tapping in a forward assist, installing a dust cover, or mounting a handguard—jobs where the main goal is just to stop the part from wiggling or twisting.

Internal Rods and Torque Isolation

This is where things get really clever. Think about trying to open a stubborn pickle jar. If you just squeeze the glass jar as hard as you can, you risk it slipping or, worse, breaking. A reaction rod is like having a special tool that locks onto the lid's threads, completely bypassing the fragile glass.

When you're applying the 30-80 ft-lbs of torque required for a barrel nut, an internal rod channels that rotational force directly into the steel barrel extension. The aluminum receiver just comes along for the ride, experiencing almost no stress at all.

A reaction rod transfers torquing forces directly between the barrel nut and the barrel extension, effectively making the aluminum receiver a non-structural component during barrel installation. This completely eliminates the risk of shearing the index pin or twisting the receiver.

The way these tools have evolved is a perfect reflection of the AR market's growth, moving from cobbled-together garage jigs to precision-engineered solutions. It's estimated that modern designs prevent damage in over 25% of DIY builds that might otherwise end in disaster. For instance, some of the newer, more innovative models even expand to eliminate any slop or rattle, which is a huge help for those non-standard billet uppers that just won't fit in a traditional block. You can learn more about these advanced vise blocks and how they secure custom receivers.

How To Choose The Right Vise Block For Your Build

Picking the wrong AR upper vise block can be just as bad as not using one at all. It’s the difference between a perfectly torqued barrel and a cracked, useless receiver. With so many different materials, designs, and platform compatibilities out there, knowing what to look for is critical to keeping your build safe, precise, and damage-free.

First things first: platform compatibility. Don't even think about trying to cram an AR-15 block onto a larger AR-10 or .308 receiver. The dimensions are completely different, and forcing a fit is a guaranteed way to apply uneven, damaging pressure. Always match the block to your specific firearm.

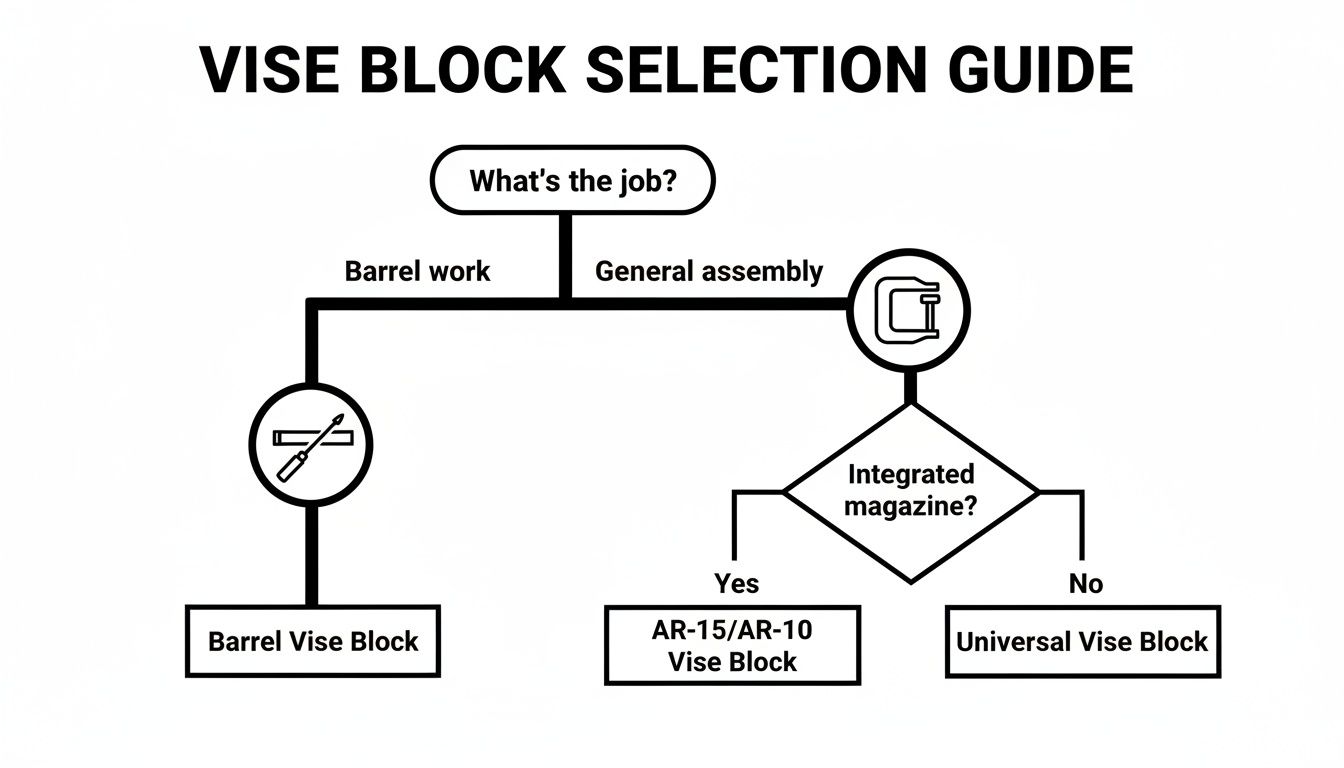

This decision tree can help you quickly figure out whether a clamshell or an internal rod is the right tool for your specific job.

As you can see, what you're actually doing—heavy-duty barrel work versus light assembly—is the biggest factor in choosing the right design.

Materials and Designs

The material and design of your vise block dictate how it performs and protects your receiver. Getting this right is probably the most important part of your decision. Let's break down the common options you'll encounter.

The table below gives you a quick side-by-side look at the most common materials and designs.

AR Upper Vise Block Comparison

| Feature | Polymer Blocks | Aluminum Blocks | Internal Support Rods |

|---|---|---|---|

| Best For | General assembly, handguard installation, light-duty work. | Extreme torque jobs where rigidity is paramount. | Barrel and muzzle device installation/removal. |

| Pros | Non-marring, affordable, protects receiver finish. | Extremely rigid, prevents any flex under high torque. | Isolates receiver from torque, prevents twisting and damage. |

| Cons | Can flex under very high torque, not ideal for stubborn barrels. | Can scratch or mar the receiver finish if not used carefully. | Higher cost, doesn't support the receiver for other tasks. |

For most home builders, a high-quality polymer block hits the sweet spot. It provides the best balance of strength and protection for common tasks.

Clamshell vs. Internal Rod

Let's dig a little deeper into the two main design philosophies. A traditional clamshell block wraps around the outside of your upper receiver, spreading the vise's clamping force evenly across its surface. This design is fantastic for preventing the thin aluminum walls from being crushed or warped. It’s the perfect choice for a huge range of tasks, from installing a dust cover to mounting an EOTech or other optics where you just need to hold the upper steady without putting stress on it.

An internal support rod (often called a reaction rod) takes a completely different approach. It slides directly into the upper and locks into the steel barrel extension lugs. This is a game-changer for barrel work because it completely isolates the aluminum receiver from any rotational stress when you're cranking on a barrel nut.

By transferring torque directly from your wrench to the barrel extension, an internal rod virtually eliminates the risk of shearing the barrel’s index pin or twisting the receiver itself.

This makes internal rods the undisputed champion for any heavy-duty barrel or muzzle device work. Some versatile clamshell products do try to bridge the gap, offering features for multiple receiver types like A2 and flattop uppers. Some even include a gas tube alignment tool, which is handy for preventing misalignment when torquing a barrel nut to its required 30-80 ft-lbs. You can find versatile vise block options on ar15discounts.com that cover a lot of bases for the average builder.

A Step-By-Step Guide To Using Your Vise Block

Alright, you've got your AR upper vise block. Now it's time to put it to work and turn what could be a frustrating, part-damaging ordeal into a smooth, controlled process. Think of this as your guide to getting it right, whether you're a first-time builder or a seasoned pro just double-checking your fundamentals.

First things first: your workspace. You absolutely need a solid workbench with a bench vise that’s bolted down tight. A wobbly setup is a disaster waiting to happen—one slip is all it takes to scratch a receiver or, worse, injure yourself.

Securing The Upper Receiver

The whole point here is to create a rock-solid, immovable foundation for your upper. We'll walk through seating the receiver in the block and then clamping the whole shebang into the vise. Getting this part right is the key to preventing warped or cracked receivers from uneven pressure.

- Open It Up: If you're working with a clamshell-style block, just separate the two halves.

- Nest the Upper: Gently place your stripped upper receiver into the bottom half. Make sure it settles in perfectly, lining up with any molded shapes like the cutouts for the forward assist or ejection port door.

- Close the Clamshell: Place the top half over the receiver. You'll want to ensure the takedown and pivot pin holes line up perfectly. Pop in the pins that came with the block to lock it all together.

- Clamp It Down: Carefully position the entire assembly into your bench vise. Begin to tighten it, but only until it's snug and doesn't move. Do not overtighten! Even with the block, an incredible amount of force from the vise can still crack an aluminum receiver. You're aiming for immobile, not crushed.

A classic rookie mistake is to crank down on the vise handle with all your might. The block is designed to spread the pressure, but it can't perform miracles. The sweet spot is just enough force to prevent the block from twisting or shifting when you start applying torque with a wrench.

Performing Common Assembly Tasks

With your upper locked in place, you’re ready to tackle the real work. The stability from the vise block is non-negotiable for jobs that require serious leverage, like installing a barrel. That same stability is just as critical for precision tasks, like when you need to accurately measure scope height for a long-range build.

Installing a Barrel Nut

This is probably the #1 reason people buy an upper vise block. Getting the torque right is everything—it impacts both the safety and the accuracy of your rifle.

- Grease is Your Friend: Always apply a quality moly grease to the receiver threads. Don't skip this.

- Torque to Spec: Grab a calibrated torque wrench and tighten the barrel nut to the manufacturer's specification. This is usually a range, like 30 to 80 ft-lbs.

- Align for the Gas Tube: That torque range gives you some wiggle room. The goal is to tighten the nut until one of the notches lines up perfectly for the gas tube to pass through into the receiver.

Timing a Muzzle Device

A vise block makes timing a muzzle brake or flash hider a simple task instead of a wrestling match.

- Thread it On: Start by hand-tightening the muzzle device onto the barrel.

- Use Shims or a Crush Washer: Add the crush washer or the necessary shims to get the device oriented correctly once it's tight.

- Final Torque: Use your armorer's wrench to apply the final torque, locking the device in its perfectly aligned position.

Follow these fundamental steps, and your AR upper vise block will quickly become one of the most valuable tools on your bench, ensuring every build is safer and more professional.

It’s always cheaper to learn from someone else’s mistakes, especially when you’re working with expensive gun parts. Even with a top-notch AR upper vise block, a few simple slip-ups can lead to a ruined receiver. Knowing what not to do is just as important as knowing the right steps.

Let's talk about the most common—and costly—mistake: cranking down way too hard on the bench vise. It's a natural impulse to think tighter means more secure, but you're not trying to crush a soda can here. The vise's job is just to hold the block steady, not to test the structural integrity of your aluminum receiver. Too much pressure will crack it, guaranteed.

Think of it like holding a bird's egg. You need just enough grip to keep it from slipping, but any more and you'll have a mess.

Using The Wrong Tool For The Job

Using the wrong block for your specific upper is another surefire way to break something. Trying to force a standard mil-spec clamshell block onto a custom billet upper is a disaster waiting to happen. The block won't fit right, creating weird pressure points instead of distributing the clamping force evenly. When you go to torque the barrel nut, you'll end up warping or even cracking the receiver.

This is exactly why so many experienced builders have switched to internal reaction rods or versatile blocks that can adapt to those non-standard receiver profiles.

And it should go without saying, but never try to use an AR-15 block for an AR-10 build. The parts look similar, but the dimensions are completely different. The fit will be sloppy, offering zero support where it matters most, and you'll likely destroy your upper the second you apply any real force.

The rule is simple: the vise block has to be a perfect match for the receiver. A poor fit makes the tool useless and puts your entire build in jeopardy.

Ignoring Proper Support and Alignment

If you don't secure the upper receiver properly, you're practically begging for a sheared barrel index pin. When you wrench on that barrel nut, all that rotational force has to go somewhere. If the block isn't holding the receiver immobile, the force transfers to the weakest point—that tiny steel pin that keeps your barrel straight. Snap.

Shearing that pin is a real headache. It can trash the threads on both your barrel extension and your upper receiver, potentially ruining two very expensive parts in one go.

The good news is that modern tools are more than up to the task. The global market for heavy-duty bench vises is expected to hit $92.5 million by 2031, which shows just how much professionals rely on solid clamping gear. High-end polymer blocks are tough as nails, with some rated to handle over 5,000 psi of pressure without leaving a scratch on your finish. Many even have a built-in gas tube alignment tool, which helps prevent the misalignment issues that pop up in nearly 20% of home barrel installs. You can see a detailed breakdown of the heavy-duty bench vise market on marketresearch.com.

By sidestepping these common blunders, you can make sure your AR upper vise block protects your investment and helps you get the job done right, every single time.

Your Questions Answered: AR Vise Block FAQs

Even after you've got the basics down, questions always pop up when you're actually at the workbench with tools in hand. Let's tackle some of the most common ones I hear about AR upper vise blocks.

Think of this as your go-to cheat sheet for those "wait, what about…" moments that can bring a build to a grinding halt. Getting these details right makes the whole process smoother and safer.

Can I Use an AR-15 Vise Block for an AR-10 Upper?

Nope, and it's not a close call. The AR-10 and other .308-pattern uppers are beefier all around compared to a standard AR-15. They need a vise block built specifically for their larger dimensions.

Trying to cram an AR-10 into an AR-15 block—or worse, having it rattle around—is a recipe for disaster. The fit will be sloppy, offering zero real support. The second you apply any real torque, you're running a massive risk of cracking or twisting that expensive receiver. Always buy a block that is clearly marked for your specific platform.

What's the Difference Between a Vise Block and a Reaction Rod?

This is a great question. An AR upper vise block is an external tool. It either clamps around the outside of the receiver (like a clamshell) or grabs it by the takedown pin lugs. Its job is to keep the vise jaws from crushing the aluminum and to stop the upper from rotating while you work.

A reaction rod, on the other hand, works from the inside. It's a steel rod that slides into the upper and locks directly into the steel barrel extension lugs. This is key because it isolates the fragile aluminum receiver from all the rotational stress. Torque is applied between the barrel and the barrel nut, leaving the receiver out of it.

For high-torque jobs like installing a barrel nut, a reaction rod is often the professional's choice because it puts virtually no stress on the upper. However, you still need a traditional vise block for other tasks, like lapping the receiver face, where a tool needs to be inserted from the front.

Do I Really Need a Torque Wrench with My Vise Block?

Yes. 100% yes. A vise block just holds the part; the torque wrench is what ensures you apply the right amount of force. It's not optional.

Barrel nuts, for example, have a specific torque range (typically 30-80 ft-lbs) for a reason. It's the engineering sweet spot for safety, reliability, and accuracy. Guessing at it by "feel" is how you end up with:

- Stripped threads on your upper receiver.

- A cracked receiver from over-tightening.

- A dangerously loose barrel from not tightening it enough.

Don't eyeball it. Always pair your vise block with a quality torque wrench. There is no safe alternative.

Will a Standard Vise Block Fit My Billet Upper Receiver?

Probably not. Billet uppers are machined from a solid chunk of aluminum, and designers love to give them unique, angular profiles and thicker walls that don't match the standard mil-spec forged shape. A typical clamshell block, designed for that classic rounded profile, simply won't close around it.

For a billet upper, your best bet is either an internal tool like a reaction rod or one of the newer, more adaptable blocks that doesn't rely on the receiver's external shape. When you're shopping, look for tools that explicitly state they're compatible with billet receivers.

At Superior Tactical LLC, we provide the mission-critical gear you need to build, maintain, and operate your firearms with confidence. From advanced optics to essential armorer's tools, our curated selection ensures you have reliable equipment for any scenario. Explore our full range of tactical accessories and get expert support for your next project at https://superiortac.com.